A Biased View of Mhs - Material Handling Supply Inc.

A Biased View of Mhs - Material Handling Supply Inc.

Blog Article

The 7-Second Trick For Mhs - Material Handling Supply Inc.

Table of ContentsThe Buzz on Mhs - Material Handling Supply Inc.Everything about Mhs - Material Handling Supply Inc.Unknown Facts About Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. for DummiesMhs - Material Handling Supply Inc. for BeginnersThe smart Trick of Mhs - Material Handling Supply Inc. That Nobody is Talking About

This line is called the line of activity. forklift rental. If all-time low of this line goes beyond the stability triangle because a lots is as well hefty or too expensive, or due to the fact that the forklift is not on a degree surface it will topple. An upright line expanding from the center of mass of the vehicle-load mix have to stay inside the security triangle to prevent the forklift from tippingThis security triangular is made by connecting the 2 front wheels and the pivot point of the back axle. The other principle to understand is the forklifts center of mass. Notification that the front and rear sides of the stability triangle are high-lighted. When unloaded, the forklifts facility of gravity is right regarding below.

Larger lots shift the center of gravity forward also further. Raising the tons also moves the center of mass ahead. In order to prevent the lift from tipping, the mixed center of mass of the lots and the lift must remain inside the stability triangle (at ground degree) at all times.

Mhs - Material Handling Supply Inc. Fundamentals Explained

If you have a well balanced lots, the lots is unlikely to impact the side-to-side center of gravity. http://dugoutmugs01.unblog.fr/2024/04/30/mhs-your-go-to-forklift-solution-in-athens-and-watkinsville-ga/. If you drive on a sloped surface, your center of gravity might pass exterior of the stability triangle and the lift might tip. Every forklift has a recognition plate that details essential details about the truck

To be certain that the center of gravity of your forklift remains inside the stability triangle, don't attempt to lift anything heavier than the identification plate enables. No issue how busy you are, you need to evaluate your forklift prior to using it. If you do find something that might impact the safety and security of the lorry you must report it promptly.

Comply with the drivers manuals provided by the tools supplier. These guidebooks define the safe operation and maintenance of forklifts. Remember, the operator is responsible for the safe operation of the forklift. Do a pre-operation evaluation prior to every shift. If the forklift is utilized all the time, examine it either prior to each change or after each change.

Some Known Details About Mhs - Material Handling Supply Inc.

It is finished in two parts: the walk-around evaluation, and, the seated examination. OSHA does not need documents of a day-to-day evaluation. It's an excellent idea to have a list to make certain you don't miss out on any type of actions. These lists can also be conserved as a part of the upkeep document.

If the forklift is an outdoor forklift with pneumatically-driven tires, examine the air stress and look for too much wear on the tires. A tire with reduced air stress might create the lift to tip when a lots is raised.

Mhs - Material Handling Supply Inc. Things To Know Before You Get This

Look for splits or various other indications of wear. Check all liquid degrees. Inspect the engine for any type of signs of wear, loose connections, or leakages. Clean up any type of excessive oil or other combustible compound. Seek splits or deformities in the forks, backrest, mast, and overhanging guard. Inspect the identification plate to make certain it is intact and readable.

Begin the engine. Always start the engine while seated in the operator's positionnever while standing along with the forklift. Examine all gauges and warning lights, and the battery or gas degree. Get acquainted with the controls. Lift and lower the forks, and turn the pole. See to it that whatever works smoothly and is plainly classified.

Facts About Mhs - Material Handling Supply Inc. Uncovered

You'll need to appear the horn at crossways, and any place vision is obstructed. Inspect the brakes by depressing the brake pedal. There need to be some resistance. Set and check the hand brake. Examine the guiding. A great deal of play or tough steering will decrease your control. Relocate the forklift forward a couple of feet.

Leakages could suggest a hydraulic trouble, and fluids left on the floor are a sliding danger. Look for stimulates or fires coming out of the exhaust system. Listen for any uncommon noises. If you locate anything incorrect with the forklift throughout the walk-around or seated examination, do not run it until it has been repaired.

Fascination About Mhs - Material Handling Supply Inc.

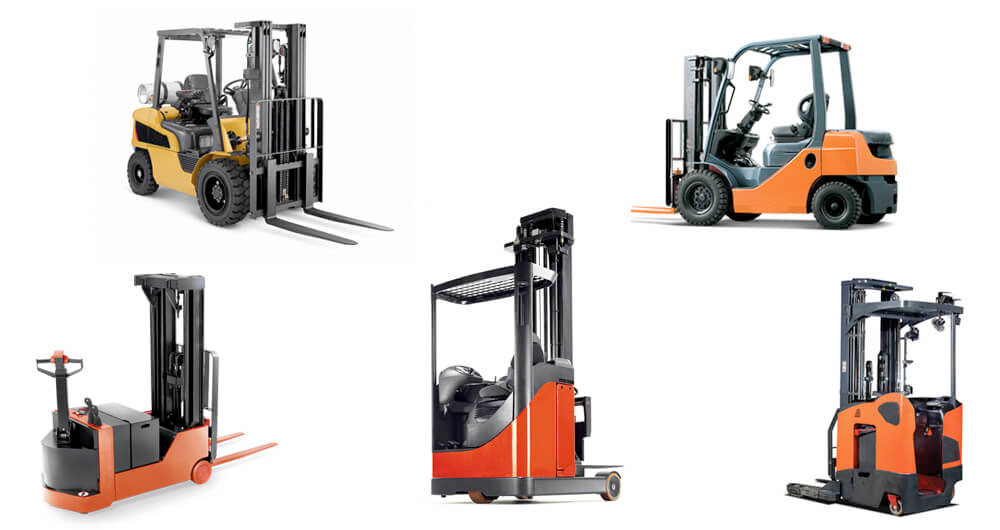

Forklifts have many moving components and items that permit the forklift to run properly. Comprehending the terminology of the parts pop over to this web-site and anatomy of a forklift is essential for efficient communication with others while on duty - https://triberr.com/mhsinc30677. Below are several of the fundamental features and parts that make up the anatomy of a forklift truck

For a lot of forklifts, the pole is created towards the front of a forklift and straight in the forklift driver's field of vision. Forklift poles feature numerous areas that raise or lower the forklift carriage together with the forks. These consist of:: Two pole phases: 3 pole phases: 4 mast areas When picking a forklift, it is important to familiarize yourself with the different features and terms of a forklift pole: the mast's lift height, the free lift elevation and the extensive elevation and the reduced height.

Report this page